Stanford, SLAC Play Key Role in New DOE Battery Consortium

‘Battery500’ to Develop New Technology for Electric Vehicles, Potentially Tripling Their Range and Lowering Their Cost

A newly formed Battery500 consortium, including researchers from Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory, will receive up to $10 million each year for the next five years to develop a new battery technology that could make electric vehicles go two to three times farther and make them less expensive.

Support for Battery500 is one of several federal and private sector actions announced on July 21 by the Obama administration that aim to boost the spread and affordability of electric vehicles in the U.S. It is part of a broader effort to fight climate change, make clean energy widely accessible and reduce dependence on oil.

Funded by the DOE’s Office of Energy Efficiency and Renewable Energy, the consortium’s 11 partners – four national labs, five research universities and two companies – will be working on making smaller, lighter and cheaper batteries that can be seamlessly adopted by battery and car manufacturers.

“Our goal is to extract every available drop of energy from battery materials while also producing a high-performance battery that is reliable, safe and less expensive,” says consortium director Jun Liu from the Pacific Northwest National Laboratory (PNNL), which leads the collaborative effort.

SLAC Director Chi-Chang Kao says, “By looking at more efficient ways of storing and using energy, Battery500 addresses important societal challenges. A growing number of Stanford and SLAC researchers are working on improving battery materials, and we’re delighted that they’ll be able to share their expertise as members of the initiative.”

Taking Electric Transportation Further

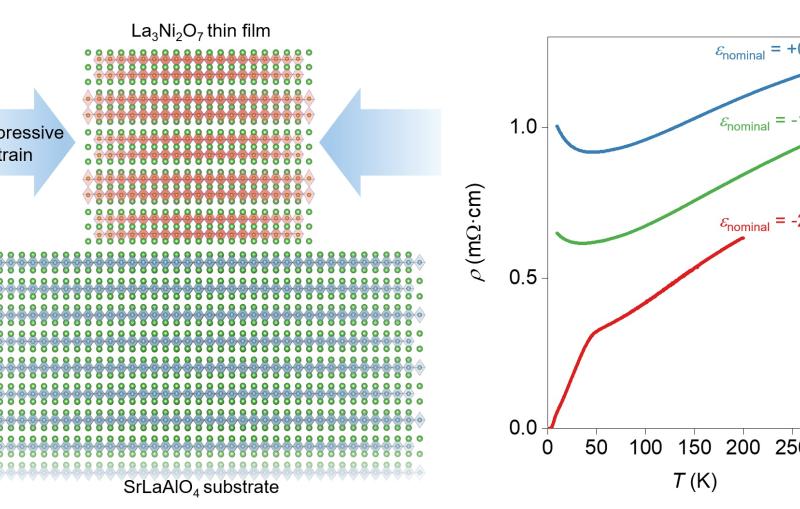

The consortium’s aggressive goal is to develop lithium batteries with two to three times the “specific energy” found in batteries that power today’s electric cars. Specific energy measures the amount of energy packed into a battery based on its weight. Because electric vehicles need to be lightweight to drive farther on a given charge, batteries with high specific energies are crucial.

“At the moment, electric cars use batteries with a specific energy of about 170 to 200 watt-hours per kilogram of battery cell, with the most advanced technology reaching 250 watt-hours per kilogram,” says Stanford’s Steven Chu, chairman of Battery500’s advisory board. “If we wanted to build compact electric cars with a small footprint that go about 300 miles per charge, then we couldn’t do it with the current battery technology.”

That’s why the consortium wants to develop batteries with 500 watt-hours per kilogram (hence the name Battery500), which would allow manufacturers to shrink the size of future electric vehicles. It would also make current models go two to three times as far.

In addition, a larger specific energy would also reduce the price of batteries and make electric cars more affordable.

“These are very ambitious goals that will require a lot of R&D work,” says Battery500’s Co-Director Yi Cui from the Stanford Institute for Materials and Energy Sciences (SIMES), a joint institute of SLAC and Stanford. “We need to identify new battery technology that is currently not used in lithium-ion batteries.”

Innovation through Collaboration

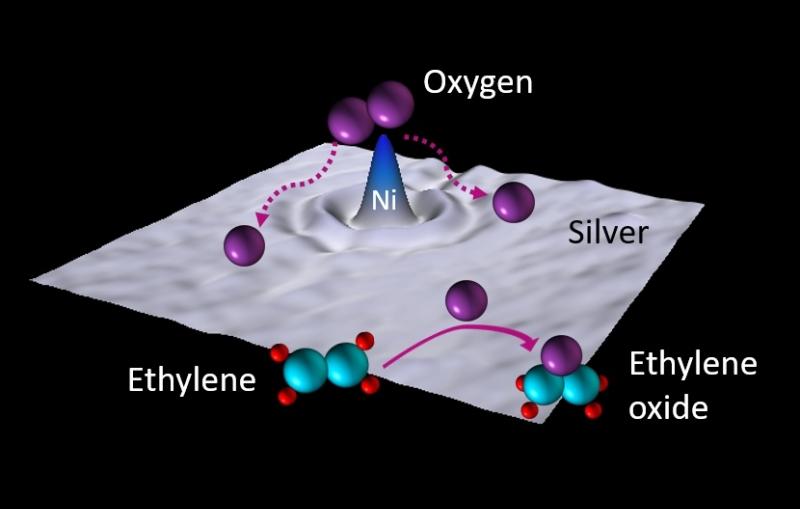

The researchers hope to reach their goals by pairing the battery’s negative electrode, which will be made of lithium, with a positive one made of other materials. Cui’s research group and others will design, synthesize and test out a number of materials, study their properties and problems, and find ways to improve them.

In this process, Battery500 will take advantage of a number of facilities, including SLAC’s Stanford Synchrotron Radiation Lightsource (SSRL). The DOE Office of Science User Facility generates intense X-rays that will be used to diagnose various battery materials on the nanoscale and under operating conditions.

A key focus of the consortium is to ensure that the technological solutions it develops meet the needs of car and battery manufacturers. While the project is ongoing, consortium members will work with industrial partners on the implementation of innovations.

Recognizing that diversity in experience and opinions often results in better solutions, the consortium will also set aside 20 percent of its annual budget to fund proposals from U.S. research groups outside the collaboration.

In addition to PNNL, Stanford and SLAC, Battery500 includes members from Brookhaven National Laboratory; Idaho National Laboratory; State University of New York, Binghamton; University of California, San Diego; University of Texas, Austin; University of Washington; and advisory board members from IBM and Tesla Motors, Inc.

Other Battery500 members from SLAC are the consortium’s operation deputy Mark Hartney and principal investigators Zhenan Bao and Michael Toney.

Editor’s note: Parts of this news feature are based on a press release issued by PNNL.

For questions or comments, contact the SLAC Office of Communications at communications@slac.stanford.edu.

SLAC is a multi-program laboratory exploring frontier questions in photon science, astrophysics, particle physics and accelerator research. Located in Menlo Park, Calif., SLAC is operated by Stanford University for the U.S. Department of Energy's Office of Science.

SLAC National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.