A new way to selectively combust contaminants streamlines ethylene production

Supported by SLAC’s catalysis group, researchers have discovered a promising method to remove contaminants during the making of polymers.

By Carol Tseng

Polyethylene surrounds us. It’s used in packaging materials, toys, medical syringes and more.

But, there’s a key step in making polyethylene that’s complicated and costly and consumes a lot of power: using a catalyst to remove acetylene from the initial stream of ethylene gas. Even in tiny amounts, acetylene can poison other catalysts used later in the process to convert ethylene to polyethylene.

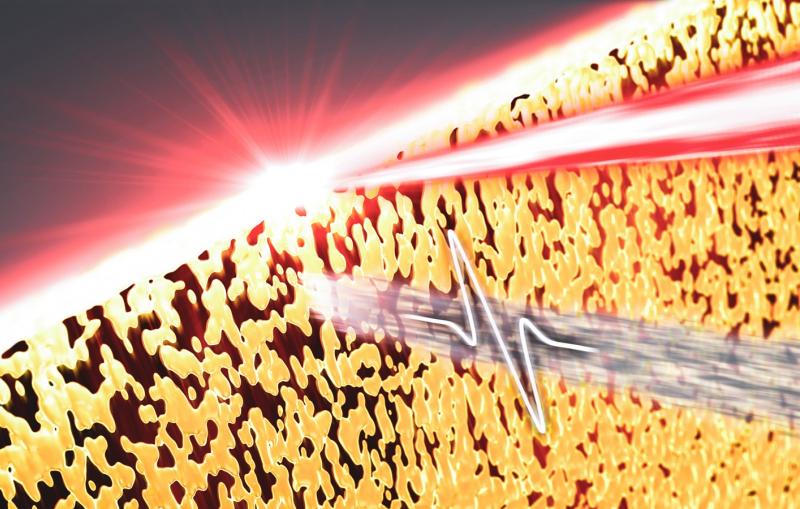

Now, a team of researchers led by the University of Minnesota, Twin Cities, and supported by the Stanford Synchrotron Radiation Lightsource (SSRL) catalysis group at the Department of Energy’s SLAC National Accelerator Laboratory have found a way to improve the process: For the first time, they removed acetylene from the ethylene stream through selective combustion, which essentially burns off the unwanted acetylene without torching everything. They reported their findings – which point to a simpler, less costly production process that will consume less energy – in Science.

To pull off this feat, the team opted for a bismuth oxide catalyst, a departure from more complicated catalyst systems used for other types of selective combustion. From previous work, they had a hunch that bismuth oxide had necessary properties that could remove acetylene without burning everything else, including ethylene, in the stream.

Normally, selective combustion requires an external supply of oxygen, but that supply is highly flammable and raises safety concerns. What’s unique about bismuth oxide is that it will give up its own oxygen during the reaction, removing the need for an outside source, and this oxygen is replenished by air through a later process step. The researchers wondered if repeated cycles of removing and adding oxygen, typical of industrial processes, would degrade the bismuth oxide, so they needed to understand what the atoms and molecules are doing during the cycles.

One of the techniques the team turned to was X-ray absorption spectroscopy at SSRL. Drawing on SSRL’s bright X-rays, the spectroscopy studies revealed that even under repeated cycling, the oxygen in bismuth oxide fully replenished without discernible changes to the catalyst.

“We were able to take oxygen out of the catalyst and put it back in multiple times,” said Matthew Jacob, lead author and graduate student at the University of Minnesota. “The catalyst changes slightly but its reactivity is not impacted.”

Co-author and SLAC Distinguished Scientist Simon R. Bare said, “This is an elegant example of how we have gone into detail to understand how oxygen is transferred from the catalyst to acetylene to combust it selectively,” adding that if they can understand how a catalyst works at the molecular and atomic levels, they may be able to adapt it for other types of combustion reactions.

Citation: Matthew Jacob et al., Science, 13 February 2025 (10.1126/science.ads3181)

This Story is based in part on a University of Minnesota Twin Cities College of Science and Engineering press release.

The research was supported in part by the DOE Office of Science. SSRL is a DOE Office of Science user facility.

Contact

For questions or comments, contact SLAC Strategic Communications & External Affairs at communications@slac.stanford.edu.

About SLAC

SLAC National Accelerator Laboratory explores how the universe works at the biggest, smallest and fastest scales and invents powerful tools used by researchers around the globe. As world leaders in ultrafast science and bold explorers of the physics of the universe, we forge new ground in understanding our origins and building a healthier and more sustainable future. Our discovery and innovation help develop new materials and chemical processes and open unprecedented views of the cosmos and life’s most delicate machinery. Building on more than 60 years of visionary research, we help shape the future by advancing areas such as quantum technology, scientific computing and the development of next-generation accelerators.

SLAC is operated by Stanford University for the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time.