A day in the life of a SLAC machine maker

At the Machine Shop, Pete Franco crafts beautiful, intricate and precise parts for the lab’s latest scientific tools.

Behind every clever scientific device – accelerator, detector, X-ray laser and more – at the Department of Energy’s SLAC National Accelerator Laboratory are the people who make their parts.

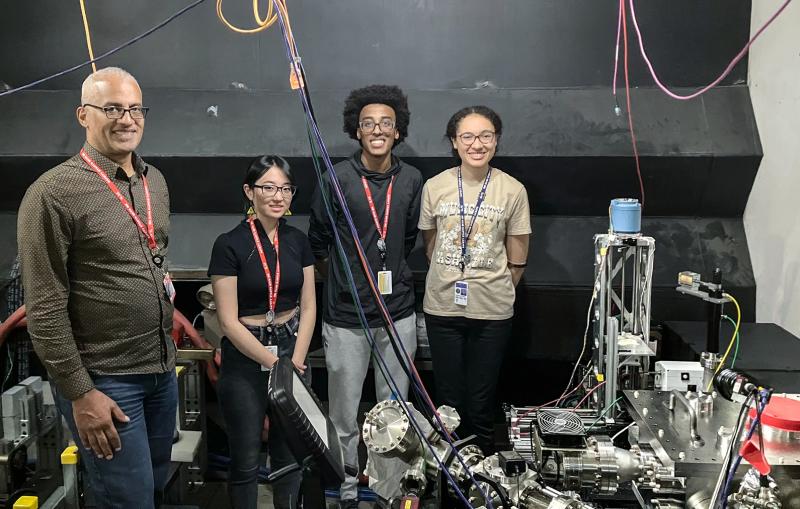

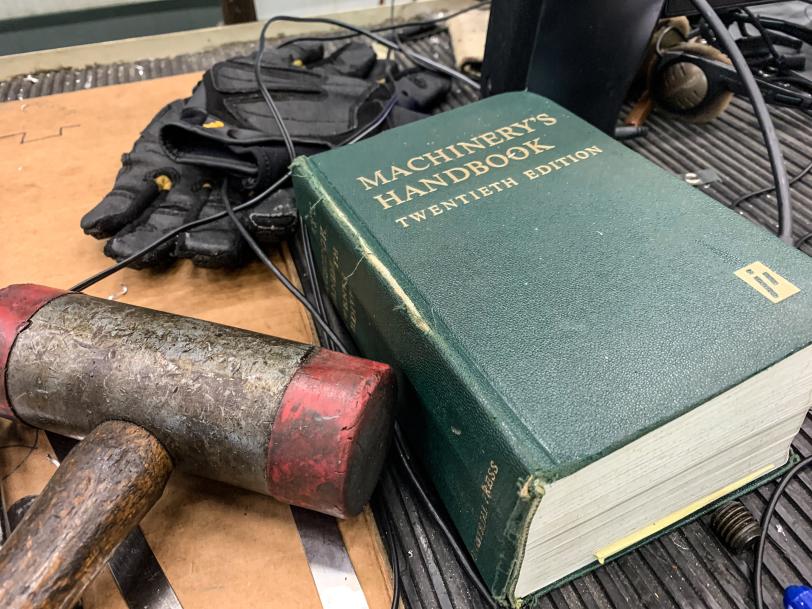

“If you can dream it up, we can make it,” says Pete Franco, lead machinist at the lab’s machine shop. He and the other 10 machinists who work there take engineers’ plans and models of their inventions and craft the pipes, clamps, gears and other parts that make those inventions work.

Making machines for science is a SLAC tradition, going back to the original accelerator that was designed and manufactured on site.

Franco, who has been working at the SLAC machine shop for 19 years, feels a sense of pride in the parts he has crafted for machines, including the storage ring and magnets for the Stanford Synchrotron Radiation Lightsource, the Accelerator Structure Test Area and the superconducting X-ray laser upgrade currently under construction at the Linac Coherent Light Source (LCLS) – all used to help scientists explore and understand fundamental mechanics of the world around us.

That pride only grew with his return to the shop in June, when the lab brought back a portion of the workforce that had been ordered to shelter in place due to COVID-19 to continue work at facilities running experiments related to the virus. Franco and colleagues helped support the recent restart of LCLS, for example, which is hosting a number of experiments looking at the inner workings of the SARS-CoV-2 virus.

The new safety regulations that had been put in place were odd at first, but in no time “cleaning, social distancing and wearing a mask became second nature,” Franco said. “I was happy to come back, especially because our main focus at the time was on COVID-19-related work. It was nice to feel part of something aiming at a cure for all of this.”

The machine shop crafts parts for facilities and for groups of scientists across the lab, which makes every day a little different, Franco said. A large machine like LCLS will be an ongoing focus, but Franco also assists with smaller tools for science. A recent project involved working with a Stanford doctor on modifications to treatment tools for ovarian cancer.

Franco is the lead machinist and backup for machine shop supervisor Denise Larsen. He also manages the department’s software interface, MasterCam, giving classes on it and answering questions when people have problems. “It makes the code that talks to the machines in the machine shop and tells them what to make,” he explains.

Part of what draws him to machining are the interesting materials he works with - tungsten, tantalum, cobalt, titanium and copper. Accuracy is paramount when shaping parts for a machine like a linear accelerator, where copper pieces graduate from square to oval to circle shapes in order to carry radio-frequency electrical currents.

One method the shop uses for cutting hard metals is called electrical discharge machining. Brass wire “burns” through metal with heat from electrical sparks. The tool can cut shapes, contours and cavities in any material that conducts electricity with an accuracy of within two ten-thousandths of an inch, Franco said. Division Director Lydia Young recently estimated that the shop used 1,250 miles of brass wire in one year to do the cutting in these machines.

A second important machine in the shop is a computer controlled vertical mill, which uses rotary cutters to carve materials along an axis, and can be used to craft complex 3D surfaces.

SLAC engineers provide printed and 3D computerized models for the designs they want, and the machine shop works closely with them to deliver. “I can set up as many as 25 different tools at a time to accomplish tasks such as milling, drilling, tapping threads – all at different depths,” Franco explains. “It just comes down to can we cut it?”

Why copper?

Some of the most common and eye-catching parts in the machine shop are made of copper, shiny as a brand new penny but much more valuable when it comes to its ability to conduct electricity. SLAC’s original 2-mile-long accelerator was constructed with more than 80,000 copper cylinders brazed together.

Franco credits his grandfather for passing down the maker genes: The elder Franco made everything he could in his own home and branded it “functional primitive” style. As a kid, the younger Franco was always building his own go-carts, and as an adult he has turned his three-bedroom, one-bath house into a six-bedroom, three-bathroom house, where he and his wife – KPIX CBS-5 traffic reporter and sports radio host Gianna Franco – live with their four children between the ages of 20 and 1.

Somehow, Franco also finds time for music. The bass player has toured with the Bay Area band The Mother Truckers and continues to gig now and then.

His work at the machine shop can be just as creative and rewarding.

Franco recently designed a crane to lift the cryogenic chamber of a massive digital camera that will go into the telescope at the Vera C. Rubin Observatory in Chile. It took months to design and construct for this particular purpose.

“It seems incredible to make such a device for this very specific use, but it might be repurposed in the future for another job,” he said.

And that’s the beauty of a place like the SLAC machine shop: The machines and materials (and the people) are always in the process of becoming or making something new.

For questions or comments, contact the SLAC Office of Communications at communications@slac.stanford.edu.

About SLAC

SLAC National Accelerator Laboratory explores how the universe works at the biggest, smallest and fastest scales and invents powerful tools used by researchers around the globe. As world leaders in ultrafast science and bold explorers of the physics of the universe, we forge new ground in understanding our origins and building a healthier and more sustainable future. Our discovery and innovation help develop new materials and chemical processes and open unprecedented views of the cosmos and life’s most delicate machinery. Building on more than 60 years of visionary research, we help shape the future by advancing areas such as quantum technology, scientific computing and the development of next-generation accelerators.

SLAC is operated by Stanford University for the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time.