Rolls-Royce, Collaborators Study Ways to Strengthen Titanium Aircraft Parts at LCLS

Rolls-Royce researchers came to SLAC earlier this month as part of a team testing titanium and its alloys, such as those used in engine parts, landing gear and other aircraft components

By Glenn Roberts Jr.

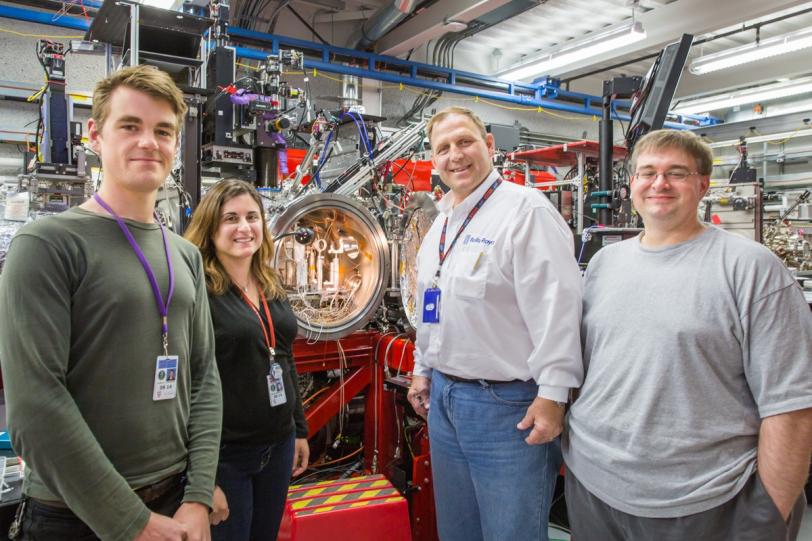

Rolls-Royce researchers came to SLAC earlier this month as part of a team testing titanium and titanium alloys such as those used in engine parts, landing gear and other aircraft components.

While the Rolls-Royce brand is also associated with luxury cars, this separate company, Rolls-Royce PLC, is a major global manufacturer of aircraft engines that power over 30 types of commercial aircraft. It is the first industrial user of SLAC's Linac Coherent Light Source X-ray laser since LCLS opened to visiting scientists in October 2009.

"Understanding materials is what drives innovation in the materials," said Michael G. Glavicic, a materials specialist for Rolls-Royce Corp. in Indianapolis, who led the experiment with David Dye of Imperial College London.

Ultimately, Glavicic said, "We want to understand what happens to a material when it's in an engine. The more we know about how an alloy behaves, the more we can be creative and figure out ways to take advantage of those properties."

The company's researchers often partner with laboratories and universities to explore hybrid materials that could find their way into products. In this case they are seeking a deeper understanding of how titanium alloys behave when pushed to extremes not found in any flight test. The results could lead to ways to make the alloys even tougher.

Lightweight, super-strong and able to withstand high heat and stress, titanium is increasingly airborne; the major application of titanium alloys is in aircraft components.

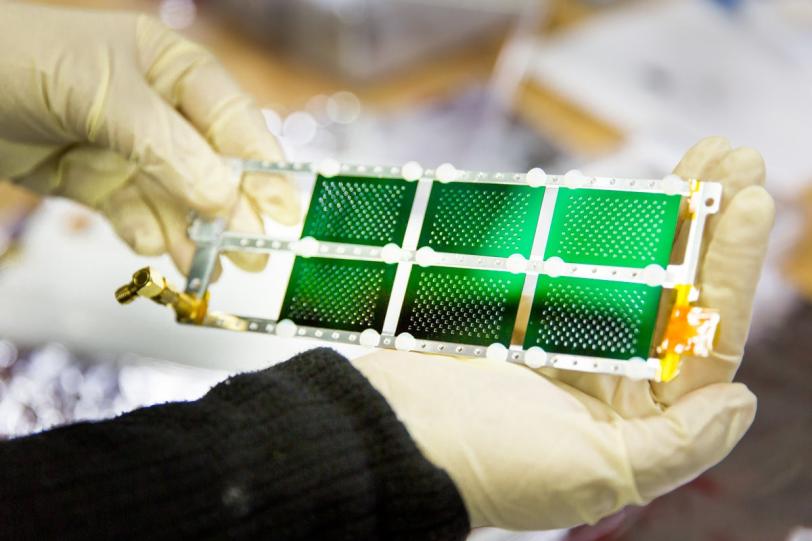

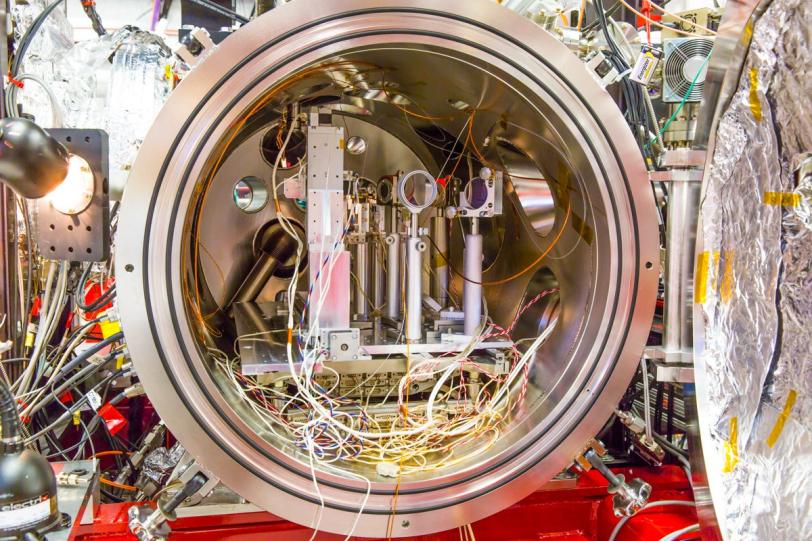

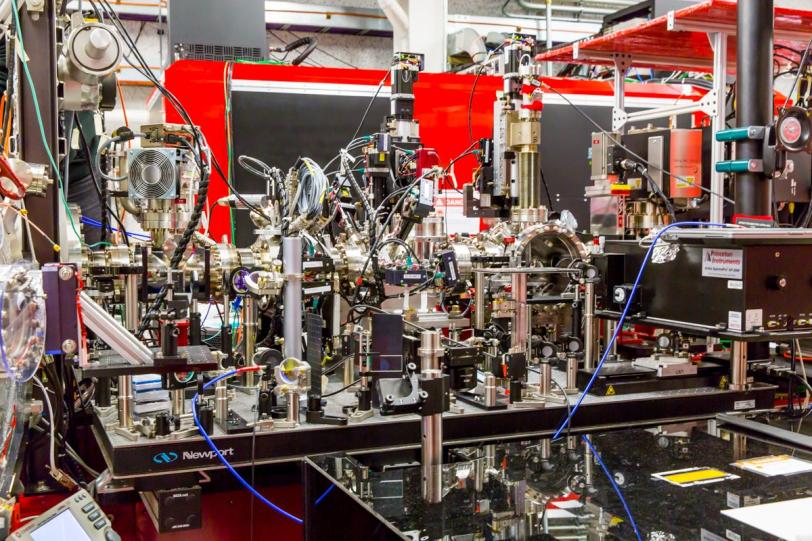

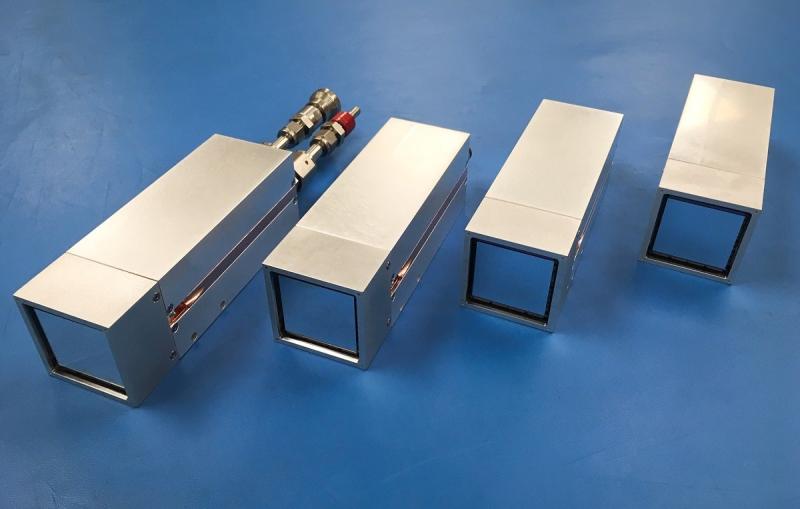

The LCLS experiment was designed to study the creation and growth of deformation in thin-foil samples of titanium and its alloys. Researchers hit the samples with powerful optical laser pulses at LCLS, and then used the X-ray laser to study how the material responded to this shock. The ultrashort, ultrabright X-ray laser pulses can uniquely capture images of samples at the nanoscale, and in increments measured in tens of femtoseconds (quadrillionths of a second).

One type of stress-caused deformation that researchers hoped to see forming is known as "twinning," named for mirror-image patterns that appear in the metal's microscopic structure. These twin regions are separated by thin boundaries that appear as lines. Like well-sewn seams across layers of fabric, the twin boundaries can actually strengthen the material.

"This is something that nobody has done before in that we're hoping to see 'twins' form – see the rate at which they form, to understand what role chemistry plays in causing things to twin," Glavicic said. "It could potentially confirm or build on current theories."

Researchers hope to use deformation mechanisms that are now considered a hindrance to improve how materials withstand stress. While commercial applications from such an experiment may be decades away, Glavicic said the goal is to gain fundamental insights about material properties that can be shared with the scientific community.

"LCLS is uniquely suited to this type of experiment," said Despina Milathianaki, an LCLS staff scientist involved in the research, "because the deformation processes often evolve in trillionths of a second," or picoseconds. The tiny focus and coherence of the LCLS X-ray pulses, she said, also allow scientists to capture images within a single "crystallite" or grain in the metal, which is an individual building block in a metal's structure.

"We hope that this is the first of many collaborations with industry partners seeking to understand fundamental materials science by exploiting the unique capabilities of LCLS," Milathianaki added.

Contact

For questions or comments, contact the SLAC Office of Communications at communications@slac.stanford.edu.

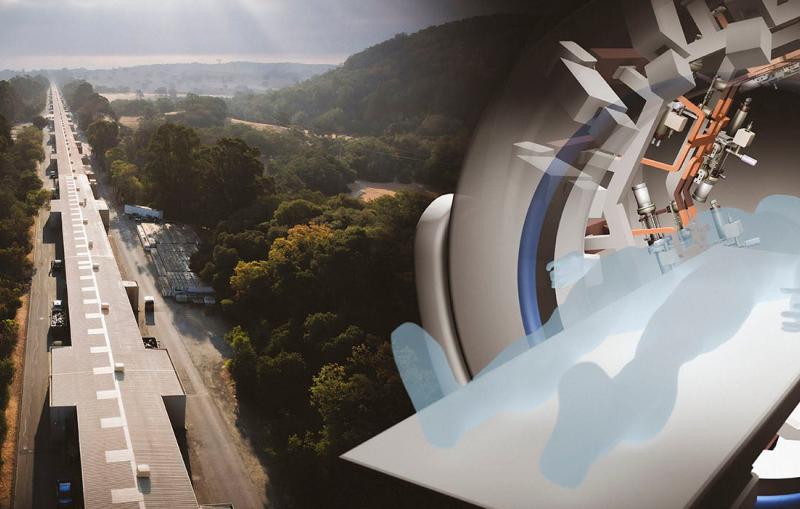

SLAC is a multi-program laboratory exploring frontier questions in photon science, astrophysics, particle physics and accelerator research. Located in Menlo Park, California, SLAC is operated by Stanford University for the U.S. Department of Energy Office of Science.

SLAC’s LCLS is the world’s most powerful X-ray free-electron laser. A DOE Office of Science national user facility, its highly focused beam shines a billion times brighter than previous X-ray sources to shed light on fundamental processes of chemistry, materials and energy science, technology and life itself. For more information, visit lcls.slac.stanford.edu.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov..