March 15, 2019

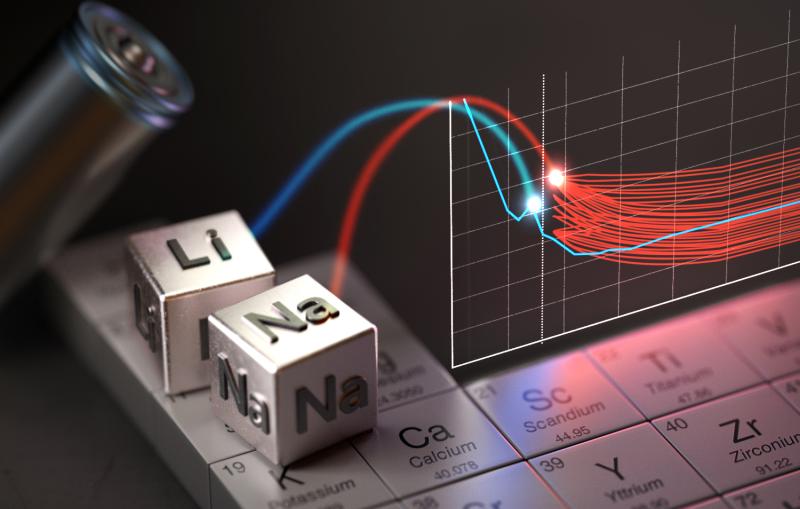

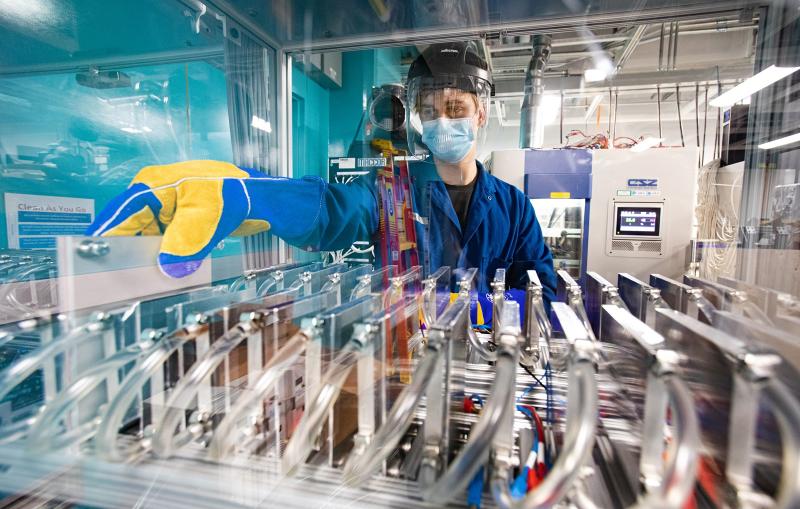

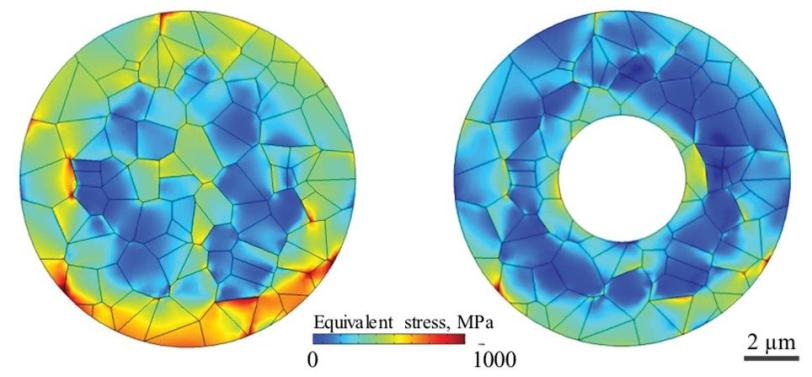

Cause of Cathode Degradation Identified for Nickel-rich Materials

Combination of research methods reveals causes of capacity fading, giving scientists better insight to design advanced batteries for electric vehicles

Dig Deeper