Fab Team Scales Up Production of Dark Matter Detectors

It's one thing to design and build a brand-new piece of technology, to test it and tune it until it works just right.

By Lori Ann White

It's one thing to design and build a brand-new piece of technology, to test it and tune it until it works just right.

It's an entirely different matter to take that one-of-a-kind instrument and mass-produce it.

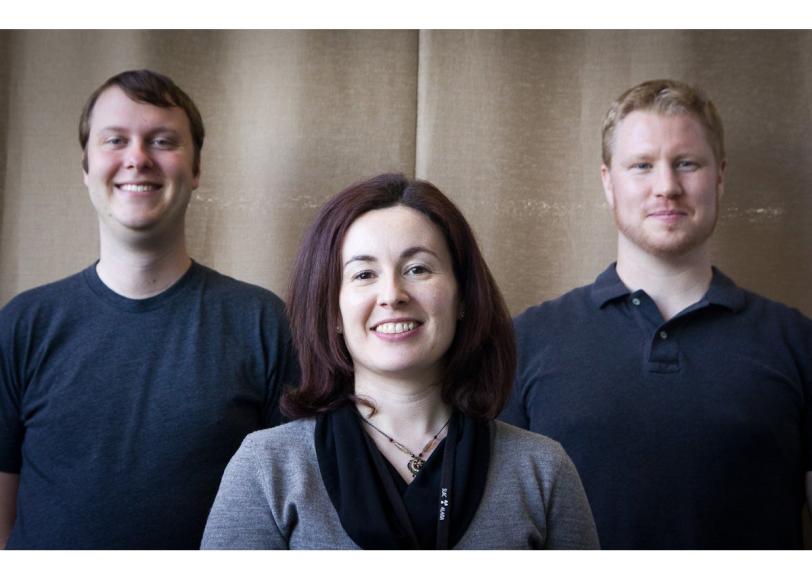

But that's essentially what the fabrication team for the Cryogenic Dark Matter Search did. Led by Astrid Tomada, an engineer with SLAC Particle Physics and Astrophysics, the team found a way to turn out six copies of the germanium particle detector every three weeks. An impressive achievement, considering the previous effort produced, on average, two detectors per month.

The team included Matt Cherry, a research assistant with Professor Blas Cabrera's CDMS group at Stanford, Rudy Resch, a research assistant, and Jasmine Hasi, an engineer, both with SLAC Particle Physics and Astrophysics.

"We needed to show it was possible," Tomada said. "That was the real reason for this through-put test."

Dark matter, the unseen type of matter that makes up more than 20 percent of the mass in the universe, has thus far only been detected through its gravitational effects on the normal matter that makes up stars, planets – and us. The CDMS experiment is designed to detect dark matter directly. Scientists hope the germanium crystals in its SLAC-built detectors, when kept at just above absolute zero, will ring like bells when struck by dark matter particles passing through.

During the more than 10 years the CDMS experiment has been refining its search technique, each phase has put more detectors deeper underground – thus the need for such a punishing schedule. Where previous phases used 4 kilograms to 9 kilograms of germanium, the next phase of the experiment, called SuperCDMS-SNOLAB, will require 100 kilograms worth of germanium detectors stacked in 12 to 19 towers, cooled to 50 thousandths of a degree above absolute zero and installed almost 3 kilometers below the surface at SNOLAB, an underground laboratory in Ontario, Canada.

According to Tomada, creating the detectors themselves has become a bigger challenge as well.

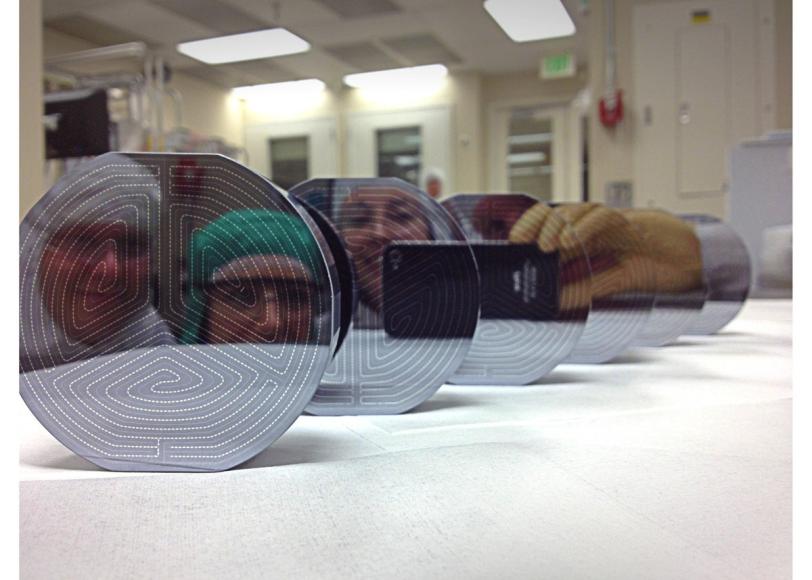

"It's very tricky in a way," she said. "Detectors are growing more complicated." Where the first germanium crystals used were 10 millimeters thick and slightly more than 75 millimeters in diameter, now they're 25.4 millimeters thick– and soon to move to 100 millimeters (just shy of 4 inches) in diameter and 33 millimeters (almost 1.3 inches) thick.

Besides the increase in size, the number of sensors per detector has doubled. Not to mention that "germanium is fragile and ‘moody’," Tomada said. The disks must also have mirror-smooth surfaces that are almost perfectly parallel to each other.

Much of the work was done using the shared facilities of the Stanford Nanofabrication Facility on the Stanford University campus. "We optimized the equipment we had," Tomada said.

Even with all the challenges, Tomada said, "The planning was the hardest part. But we planned so well the actual process went smoothly."

She credits her two assistants with keeping her sane during the project. Like Tomada, both Cherry and Resch began their careers with bachelor's degrees in physics. However, all three graduated with a desire to do hands-on device fabrication. As Tomada says, she enjoys the "instant satisfaction" of engineering work.

Whatever the alchemy of their teamwork, it resulted in high-quality detectors, said Paul Brink, a long-time member of the CDMS team, first with Stanford University and now with SLAC. "We tested one with our colleagues at Berkeley and it looks very good," he said. "We've confirmed the process."

Richard Partridge, head of the SLAC CDMS contingent, said detector construction is “a big responsibility for SLAC. That's the heart of the experiment – making these chunks of germanium into something that works."

Tomada said she foresees little problem with moving to the 100 millimeter-diameter disks required for the next phase, now that the kinks have been worked out of the process: "We have our foundation," Tomada said. "It's pretty solid right now."

Editor's note: To find out more, check out "CDMS at SLAC," the next in the regular series of lunchtime talks presented by the SLAC Association for Student Seminars. The talk, by CDMS graduate student Kristi Schneck, is Wednesday at 12:30 p.m. in the Kavli third floor conference room.

(Photo by Lori Ann White)

(Photo by Matt Cherry)